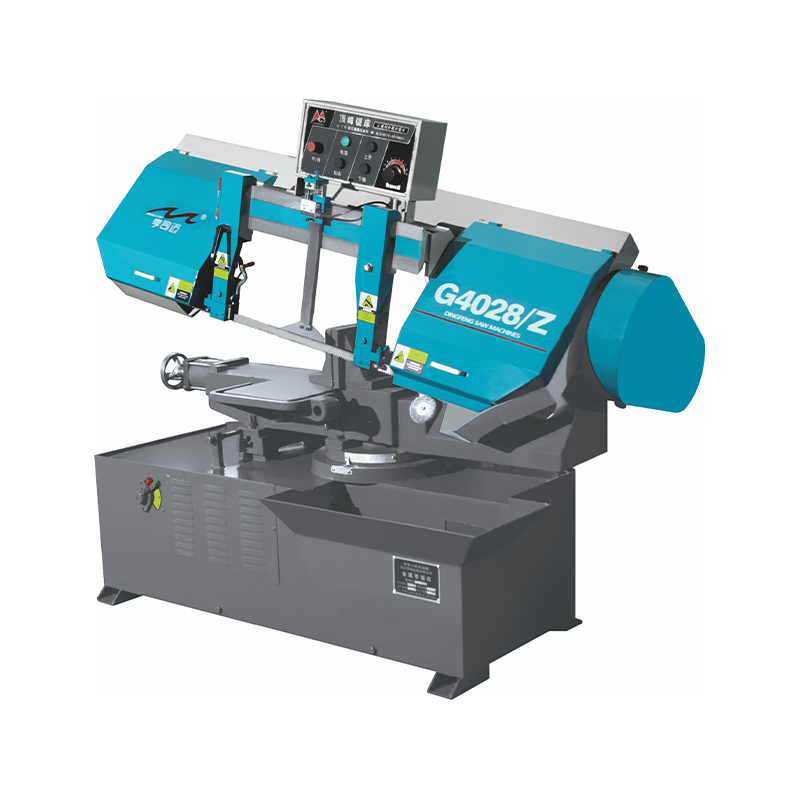

Vertical band saws are metal cutting machines primarily characterized by their vertical structure, using a vertically mounted saw blade for cutting. Their main features include:

- Compact Structure, Saving Space

Vertical band saws typically save more factory space than horizontal band saws. For companies with compact production workshop layouts, vertical equipment can be flexibly arranged in the production line and combined with automatic feeding systems or lifting platforms to optimize production line processes.

- High-Precision Machining

High-precision vertical band saws achieve precise cutting of steel and other metal materials through rigid machine tool structures, precision guide rails, and stable saw blade transmission. They offer small cutting errors and high repeatability, suitable for mass production and high-demand parts processing.

- Flexible Operation

The vertical cutting method of vertical band saws makes material placement and adjustment more convenient. Especially for cutting long materials, irregularly shaped steel, or thick plates, the vertical structure effectively reduces material slippage, improving cutting safety and stability.

- Wide Range of Applications

The equipment can process round steel, square steel, rectangular steel, steel pipes, and profiles. Some equipment can also cut non-ferrous metals such as aluminum and copper. By changing different types of saw blades and adjusting cutting parameters, it can meet various metal processing needs.

Applications of Vertical Band Saws in Modern Production

- 1. Mechanical Parts Processing

In the mechanical manufacturing industry, various parts usually require precise dimensions and neat surfaces. Vertical band saws, combined with vertical cutting and automated feeding, can achieve efficient processing of small batches of multi-specification parts. For example, the cutting of parts such as gear shafts, connecting plates, and support frames can be completed using vertical band saws, improving production efficiency.

- 2. Steel Structure Processing

In the manufacturing of building and industrial steel structures, there is a wide variety of materials and complex dimensions. Vertical band saws can perform angle cutting on shaped steel, channel steel, angle steel, etc., achieving precise processing of structural connecting parts to meet the needs of construction and engineering installation.

- 3. Pipe and Profile Cutting

In pipe processing and mechanical equipment manufacturing, the cutting requirements for pipes or profiles are high. Vertical band saws can achieve multi-angle cutting by adjusting the saw blade angle and feed speed, adapting to the production of complex structural parts and improving material utilization.

- 4. High-End Equipment Manufacturing

In the fields of aerospace, rail transit, and precision equipment manufacturing, there are strict requirements for the precision of metal parts and the surface finish of cuts. Vertical band saws, through their high-rigidity machine structure and precise control, achieve high-precision cutting, providing a reliable material basis for subsequent welding, assembly, or heat treatment.

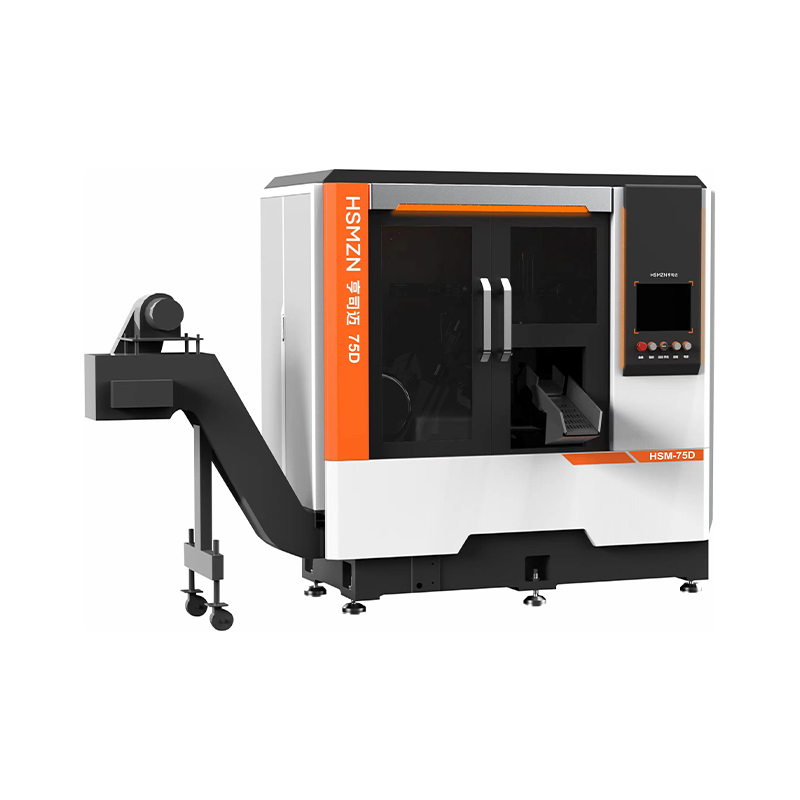

Intelligent and Automated Features of Vertical Band Saws

With the development of intelligent manufacturing, modern vertical band saws are gradually moving towards automation and digitalization:

- CNC Control

Through the CNC system, automatic feeding, precise setting of cutting length and angle can be achieved. When processing different batches of materials, operators only need to adjust the program to complete continuous cutting, reducing manual operation and improving production efficiency.

- Data Monitoring and Recording

Some high-precision equipment can monitor cutting progress, saw blade wear, and processing status in real time, and record the data in the production management system. Companies can optimize production plans through data analysis, reducing material waste and equipment downtime.

- Flexible Cutting Function

Vertical band saws can achieve multi-angle cutting. By rotating or tilting the workbench, bevel cutting and irregular shape cutting tasks can be processed, meeting diverse production needs.

- Safety and Intelligence

Modern equipment is equipped with sensors and emergency stop systems, which can automatically stop operation when material jamming, overload, or abnormal vibration is detected, ensuring operational safety.

Production Efficiency and Material Utilization

Vertical band saws have significant advantages in production efficiency and material utilization:

- Space Saving and Improved Production Line Utilization

The vertical structure is suitable for compact workshop layouts, and when combined with other automated equipment, it can optimize the overall production process.

- High Precision Reduces Rework

Precise cutting reduces the need for material trimming, improves raw material utilization, and lowers production costs.

- Strong Continuous Production Capacity

Combined with automatic feeding and CNC programs, the equipment can operate continuously, adapting to mass production and small-batch, multi-variety mixed production modes.

Daily Maintenance and Management

The long-term stable operation of high-precision vertical band saws depends on standardized maintenance:

- Saw Blade Maintenance

Regularly check the saw blade for wear and proper tension, and replace or sharpen it as needed to ensure cutting accuracy.

- Lubrication of Guide Rails and Sliding Parts

Keep the guide rails and sliding parts lubricated to prevent friction, jamming, and part wear.

- Electrical and Control System Inspection

Regularly inspect the CNC system, sensors, and electrical components to ensure the normal operation of automated functions.

- Cutting Fluid and Chip Management

Maintaining clean cutting fluid and promptly removing chips prevents negative impacts on cutting quality and extends equipment lifespan.

Scientific daily maintenance not only extends equipment life but also ensures cutting accuracy and production continuity.

Trends in Vertical Band Saw Development

- Intelligent Manufacturing and Digitalization

Future equipment will rely more on intelligent control and data analysis to optimize production planning, monitor processing, and track quality.

- Flexibility and Multifunctionality

Modular design will enable equipment to quickly switch between different processing tasks, meeting the needs of diversified, small-batch production.

- Energy Saving and Environmental Protection

New generation equipment optimizes design in motor efficiency, saw blade materials, and cutting fluid management, reducing energy consumption and noise, and meeting green manufacturing requirements.

- Intelligent Safety

Combining AI and sensor technology, it achieves anomaly detection and automatic protection, improving production safety and reducing operating risks.

Recommendations for Choosing a Vertical Band Saw

When choosing a vertical band saw, companies should consider the following factors:

- Cutting accuracy and repeatability: Meeting the dimensional requirements of production parts.

- Automation and intelligence level: Compatibility with the production line's digital system.

- Material adaptability: Ability to cut the required steel and other metal materials.

- Safety and ease of operation: Whether the protective design is complete and operation is convenient.

- Ease of maintenance and repair: Whether daily maintenance and parts replacement are simple.

Choosing equipment based on production needs helps improve production efficiency, reduce material waste, and improve product quality.

Industrial high-precision metal processing vertical band saws, as important equipment in modern manufacturing, have significant advantages in production efficiency, processing accuracy, operational safety, and material utilization.

中文简体

中文简体

English

English  русский

русский  عربى

عربى

+86-13905781129 (wechat) / +86-18767832868

+86-13905781129 (wechat) / +86-18767832868  +86-0578-3559058

+86-0578-3559058