Zhejiang Hengsimai Intelligent Machinery Co., Ltd.

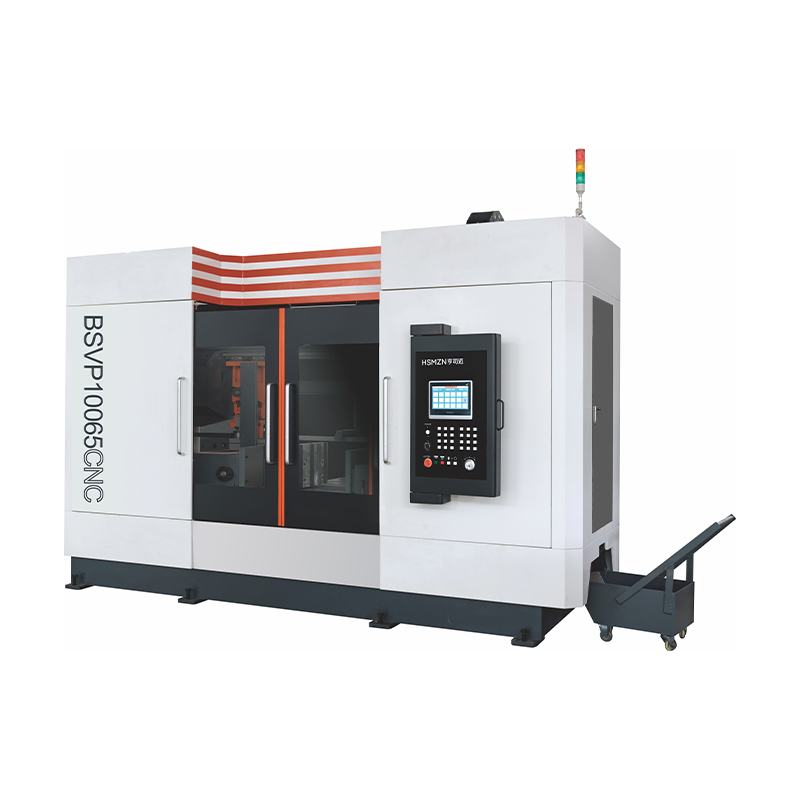

With over 30 years of expertise, HENGSIMAI Intelligent Machinery stands as a leading

manufacturer of intelligent metal sawing equipment in China. From design and R&D to production and service, the company integrates innovation, precision, and reliability into every machine. Committed to advancing

intelligent sawing technology and global manufacturing standards, HENGSIMAI continues to shape the future of metal cutting with efficiency and trust.

Manufacturing Excellence:

Over 30,000㎡ modern facility equipped with advanced CNC centers, laser systems, and robotic welding lines, ensuring precision and consistency.

Intelligent Innovation:

Pioneering in intelligent CNC and automated sawing systems, driving the industry toward smarter, more efficient solutions.

Global Reach:

Over 150 branches across China and exports to 20+ countries worldwide, earning international trust and recognition.

Vision & Values:

Driven by innovation, integrity, and collaboration, HENGSIMAI strives to set new benchmarks in intelligent sawing technology.

中文简体

中文简体

English

English  русский

русский  عربى

عربى

+86-13905781129 (wechat) / +86-18767832868

+86-13905781129 (wechat) / +86-18767832868  +86-0578-3559058

+86-0578-3559058